Challenges Ahead for America’s Supply Chain Post-Interim Agreement

3 min read

As January approaches, the timeline for the interim agreement’s expiration signals impending challenges for America’s supply chain. A potential disruption could pose significant threats to the delicate balance within the supply chain network.

The need for swift resolution looms large, with stakeholders bracing for impact in case of a further strike. The interconnected nature of global trade magnifies the potential consequences of any disruption, with ripple effects felt far and wide.

Businesses are urged to prepare contingency plans and diversify supply sources to mitigate risks. Maintaining a robust and adaptable supply chain strategy is imperative in navigating uncertainty and potential disruptions ahead.

Collaboration among industry players and swift, decisive action will be essential in safeguarding the supply chain’s integrity. Proactive measures and open communication channels will be crucial in addressing challenges and minimizing the impact on businesses and consumers alike.

As the deadline draws near, the spotlight is on finding sustainable solutions that ensure the resilience and continuity of America’s intricate supply chain network. Stakeholders must work together to proactively address potential threats and fortify the supply chain against future uncertainties.

With the interim agreement deadline on the horizon, additional factors come into play as America’s supply chain faces looming challenges. One critical aspect to consider is the impact of geopolitical tensions on trade flows and transportation routes. These dynamics can significantly affect the efficiency and reliability of supply chain operations.

Key questions arise regarding the sustainability of current supply chain practices and the need for long-term strategic adjustments. How can companies strike a balance between cost-effectiveness and supply chain resilience in an increasingly volatile global landscape? What role will technology and innovation play in transforming traditional supply chain models to enhance flexibility and responsiveness?

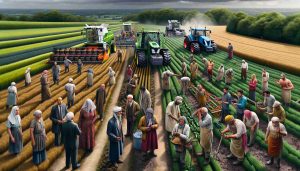

One of the primary challenges revolves around the complexity of supplier networks and the inherent risks associated with single-sourcing dependencies. Diversifying supply sources is crucial, yet it can also introduce challenges related to quality control, consistency, and logistics coordination. Balancing these trade-offs requires a nuanced approach to risk management and operational agility.

Advantages of navigating supply chain challenges proactively include enhanced agility in responding to market dynamics and disruptions, improved customer satisfaction through reliable service delivery, and strengthened relationships with key partners. However, proactive measures may entail upfront investments in technology, workforce training, and supply chain redesign, which can strain resources and require careful planning to achieve sustainable outcomes.

Disadvantages of reactive supply chain management include increased vulnerability to sudden disruptions, higher operational costs incurred from expedited shipping and alternative sourcing, and potential reputational damage due to service disruptions or product unavailability. Failing to address supply chain vulnerabilities promptly can erode competitive advantage and erode customer trust over time.

Addressing these challenges necessitates a holistic approach that encompasses risk assessment, scenario planning, supplier relationship management, and continuous performance monitoring. By fostering collaboration across the supply chain ecosystem and embracing data-driven insights, businesses can proactively identify and mitigate potential bottlenecks before they escalate into critical issues.

For further insights on supply chain resilience and risk management strategies, organizations can explore resources from established industry leaders and academic institutions. Supply Chain Brain offers a wealth of articles, webinars, and case studies on emerging trends and best practices in supply chain management that can inform strategic decision-making.